Vibration Monitoring System

A vibration monitoring system is a set of tools, devices, and software designed to measure, analyze, and manage vibrations in machinery and structures.

Vibration monitoring is crucial in various industries to ensure the proper functioning of equipment, identify potential issues, and prevent catastrophic failures. Here are key components and aspects of a vibration monitoring system:

- Accelerometers: Spare accelerometers for measuring vibration levels on various parts of the turbine and associated machinery.

- Vibration Transmitters: Replacement vibration transmitters to convert vibration signals into electrical signals for monitoring systems.

- Vibration Monitoring System Controller: Spare controllers for the vibration monitoring system to process and analyze vibration data.

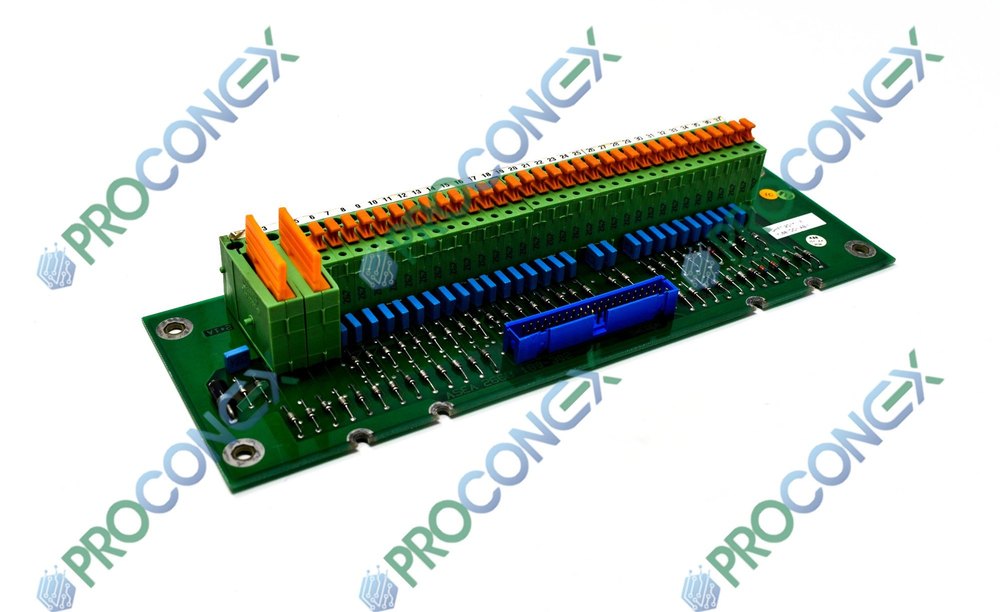

- Cabling and Connectors: Extra cables and connectors for connecting accelerometers and other components to the vibration monitoring system.

- Junction Boxes: Spare junction boxes for organizing and connecting multiple accelerometer signals.

- Signal Conditioners: Replacement signal conditioners to enhance the quality of the vibration signals before transmission.

- Mounting Accessories: Brackets, studs, and other mounting accessories for installing accelerometers securely on machinery.

- Monitoring Software: Spare or updated monitoring software to analyze and visualize vibration data.

- Data Loggers: Additional data loggers for recording and storing vibration data over time.

- Bearing Condition Sensors: Sensors specifically designed to monitor the condition of bearings, a critical aspect of vibration monitoring.

- Temperature Sensors: Spare temperature sensors to monitor the temperature of machinery components alongside vibration data

- Power Supplies: Additional power supply units for providing power to vibration monitoring components.

- Display Panels and Human-Machine Interface (HMI) Components: Spare display panels, touchscreens, and HMI components for the control interface.

- Communication Modules: Spare communication modules for interfacing with other components and control systems.

- Signal Processing Units: Replacement signal processing units for further analysis of vibration signals.

- Manuals and Documentation: Keep updated manuals and documentation for reference and troubleshooting.

- Testing and Calibration Tools: Tools for periodic testing and calibration of vibration sensors and monitoring devices.

- Seals and Gaskets: Replacement seals and gaskets to ensure the integrity of vibration sensor installations.

- Data Analysis Tools: Spare or updated software tools for in-depth analysis of vibration data

- Remote Monitoring Systems: Components for remote monitoring, allowing real-time assessment of vibration data from a distance.

When procuring these spares, it’s advisable to work closely with the original equipment manufacturer (OEM) or authorized dealers to ensure compatibility and compliance with system specifications. Regular maintenance, periodic inspections, and proactive replacement of critical components contribute to the long-term reliability and performance of vibration monitoring systems in industrial applications.

Industries such as manufacturing, energy, aviation, and transportation commonly use vibration monitoring systems to improve equipment reliability, reduce downtime, and enhance overall safety and efficiency.

Spares

Maintaining an inventory of spare parts for your vibration monitoring system is crucial to minimize downtime and ensure the continuous operation of the system. Here is a list of common spare parts you may consider for a vibration monitoring system:

- Vibration Sensors/Transducers: In our company, we offer accelerometers, velocity sensors, and displacement sensors that ensure compatibility with the specific monitoring points in your system.

- Cables and Connectors: In our inventory, we stock spare cables of various lengths and types, along with connectors for sensors, data acquisition units, and other components.

- Data Acquisition Units: We maintain spare units with the same specifications as the primary data acquisition unit. Additionally, we ensure compatibility with the sensors and the overall monitoring system.

- Signal Conditioning Equipment: We keep spare signal conditioning devices to uphold signal quality. Additionally, we take into account spare filters and amplifiers.

- Vibration Analyzers: We store backup vibration analyzers or portable analysis tools, along with spare batteries and chargers.

- Power Supplies: In our inventory, we maintain spare power supplies for sensors, data acquisition units, and other components, ensuring compatibility and the correct voltage specifications.

- Computer Hardware/Server: We stock spare components like network interface cards, memory modules, or backup servers. We make sure these components are compatible with the software and meet the data storage requirements.

- Storage Devices: In our inventory, we keep spare hard drives or storage devices for data backup, and we also consider external backup solutions or cloud-based storage options.

- Alarm and Notification Devices: We maintain spare alarm units and notification devices, ensuring compatibility with the monitoring system.

- Software Licenses and Documentation: We keep backup copies of software licenses and installation files, along with comprehensive documentation on system configuration, settings, and calibration procedures.

- Training and Documentation: We offer training materials for maintenance personnel, including troubleshooting guides and documentation on spare part replacement procedures.

- Emergency Response Kit: In our inventory, we have kits equipped with essential tools for the swift replacement or repair of components, including spare fuses, screwdrivers, and other necessary tools.

- Vendor Contact Information: In our records, we maintain contact details for equipment vendors and technical support, along with service contracts and warranty information.

- Calibration Tools: In our toolkit, we possess tools for calibrating sensors and ensuring accuracy, along with spare calibration standards.

- Enclosures and Mounting Hardware: In our inventory, we have spare enclosures designed to protect sensitive components, along with mounting brackets and hardware for sensors and equipment.

- Seals and Gaskets: In our stock, we keep spare seals and gaskets tailored for sensors and enclosures to ensure a watertight and secure environment.

- Upgrades and Compatibility: In our inventory, we store spare parts or adapters designed to accommodate system upgrades, ensuring compatibility with the latest software and hardware updates.

As a company, we consistently review and update our inventory of spare parts while conducting preventive maintenance to identify potential issues before they lead to system failures. Maintaining a meticulously organized inventory of spare parts is integral to ensuring the efficient and reliable functioning of a vibration monitoring system.

Repairs

When it comes to repairing a vibration monitoring system, our systematic approach allows us to quickly identify and address issues. Here are the steps you can follow for vibration monitoring system repairs:

- Troubleshooting: We begin by identifying the symptoms of the issue. Is it a sensor malfunction, connectivity problem, or a failure in the data acquisition unit? We review recent data and system logs to gather information about when the issue started and any patterns associated with it.

- Isolation of Fault: We utilize diagnostic tools like vibration analyzers or monitoring software to pinpoint the fault to a specific component or sensor. We check for loose connections, damaged cables, or faulty sensors.

- Sensor Calibration: If the issue is related to sensor readings, we check and recalibrate the sensors if necessary. We also ensure that the sensors are properly installed and oriented according to specifications.

- Data Acquisition Unit Inspection: We inspect the data acquisition unit for any physical damage or abnormalities. This involves checking power supplies, internal connections, and interface cables.

- Signal Conditioning and Amplification: We examine signal conditioning components for proper functionality, conducting tests on amplifiers and filters to identify any issues that may affect signal quality.

- Software and Configuration Check: We verify the software settings and configurations, ensuring that software licenses are valid and up-to-date.

- Power Supply Check: We conduct tests on power supplies for sensors, data acquisition units, and other components to ensure the stability and compliance of power sources with system requirements.

- Replacement of Faulty Parts: We replace malfunctioning sensors, cables, connectors, or other components that are identified during the troubleshooting process. Utilize spare parts from your inventory or promptly place orders for replacements.

- Functional Testing: Following repairs or replacements, we perform functional tests to verify the system’s proper operation. This involves monitoring real-time data and comparing it with baseline measurements to ensure alignment with expected performance standards.

- Documentation Update: We revise the system documentation to incorporate specifics of the repair, replaced components, and any adjustments implemented. A detailed record of maintenance and repair activities is maintained for future reference.

- Preventive Maintenance: We institute preventive maintenance measures to mitigate the risk of recurring issues. This involves conducting regular inspections and tests on components to proactively identify potential problems before they escalate into system failures.

- Vendor Support: In cases where the issue persists or proves challenging to diagnose, we engage the vendor for technical support. We adhere to their guidance and follow their recommendations for advanced troubleshooting.

- Training: We guarantee that maintenance personnel are sufficiently trained to diagnose and address issues. Continuous training programs are implemented to keep them abreast of the latest maintenance procedures, ensuring their skills and knowledge remain up-to-date.

- System Upgrades: If necessary, we contemplate upgrading system components or software, particularly when issues are attributed to compatibility issues or outdated technology. This proactive approach ensures the system remains up-to-date and operates optimally.

By adhering to a systematic repair process and maintaining a well-documented maintenance plan, we aim to minimize downtime and enhance the reliability of our vibration monitoring system. Conducting regular checks and implementing preventive measures are integral to sustaining a healthy and efficient monitoring system.

Testing & Certification

- Functional Testing: We conduct functional tests to verify the proper operation of each spare part, encompassing accelerometers, vibration transmitters, controllers, and communication modules.

- Calibration Testing: We regularly calibrate accelerometers and other sensors to ensure precise measurement of vibration levels.

- System Integration Testing: We conduct tests to assess the integration of the vibration monitoring system spares with the overall turbine control system.

- Communication Testing: We verify the communication modules by conducting tests on data transmission and reception between the vibration monitoring system components and the control system.

- Vibration Signal Analysis: We conduct tests to analyze vibration signals under various operating conditions, ensuring that the system can accurately detect and assess vibrations indicative of machinery health.

- Temperature Testing: We perform tests on temperature sensors in conjunction with vibration monitoring to ensure their accurate and reliable operation, particularly under extreme conditions.

- Power Supply Testing: We ensure that power supply units meet the specified voltage and current requirements, conducting thorough verification to guarantee they can provide stable power to all components of the vibration monitoring system.

- Environmental Testing: We subject the vibration monitoring system spares to environmental tests, incorporating variations in temperature, humidity, and other conditions to assess their performance in real-world scenarios.

- Data Accuracy and Precision Testing: We verify the accuracy and precision of the data collected by the vibration monitoring system under controlled conditions.

- Certification for Compliance: We obtain certification from recognized testing laboratories or certification bodies, ensuring that the vibration monitoring system spares comply with relevant industry standards and regulations.

- Documentation and Traceability: We maintain detailed documentation of the testing procedures, results, and certifications for each spare part. Establishing traceability ensures a clear link between each component and its testing and certification records, fostering accountability and effective quality control.

- Reliability and Durability Testing: We conduct tests to assess the long-term reliability and durability of vibration monitoring system spares, incorporating accelerated aging tests to simulate prolonged use.

- Software Verification: If the vibration monitoring system involves software for data analysis, we ensure that the software undergoes thorough verification and validation processes to guarantee accuracy and reliability.

- User Training: If applicable, we conduct training sessions for users on the proper use and interpretation of vibration monitoring system data.

- Periodic Recertification: We establish a schedule for periodic recertification to ensure that the vibration monitoring system spares continue to comply with standards over time.

Working with experienced and qualified testing laboratories, and involving the original equipment manufacturer (OEM) when necessary, can enhance the effectiveness of the testing and certification process. This comprehensive approach helps maintain the performance and reliability of vibration monitoring systems in industrial applications.

Spare Parts & Repairs Availability

Services & Solutions at Proconex for vibration monitoring system

Reliable Expertise

With years of experience, our team brings reliable expertise to every spares and repair service we provide.

Quality Assurance

We ensure that all spare parts and repairs meet the highest quality standards, contributing to the long-term reliability of your turbine control parts and spares.

Customer Support

Our dedicated support team is ready to assist you. Whether you need guidance on spare parts or emergency repairs, we are just a call away.