Turbine control panels

They are essential components in various industrial applications, particularly in power generation and mechanical systems involving turbines. These panels help operators watch and manage turbines to make sure they work well, stay safe, and perform their best.

The specific features and functions of a turbine control panel may vary depending on the type of turbine and its application such as;

- HMI (Human-Machine Interface): The control panel typically includes a user-friendly interface that allows operators to interact with the turbine control system. This can include touchscreens, displays, and input devices.

- Control System: The control system is the brain of the turbine control panel. It processes information from various sensors and implements control strategies to regulate the turbine’s speed, power output, and other parameters.

- Emergency Shutdown (ESD) System: Turbine control panels often incorporate an emergency shutdown system that can rapidly and safely shut down the turbine in case of a critical fault or emergency situation.

- Instrumentation and Sensors: Various sensors are employed to monitor essential parameters such as temperature, pressure, vibration, and speed. The data from these sensors are processed by the control system to make real-time decisions.

- Start/Stop Controls: These controls allow operators to initiate the start-up or shutdown procedures for the turbine.

- Speed and Load Controls: Turbine speed and load are critical parameters that need to be controlled. The control panel enables operators to set and adjust these parameters based on operational requirements.

- Alarms and Indicators: The panel includes visual and audible alarms to alert operators to any abnormal conditions or malfunctions. Indicators provide real-time feedback on the status of various components.

- Communication Interfaces: Turbine control panels often have communication interfaces to connect with other control systems, supervisory control and data acquisition (SCADA) systems, and external devices.

- Data Logging and Analysis: Some control panels have built-in data logging capabilities, allowing operators to review historical data and trends. This information can be valuable for maintenance and performance analysis.

- Remote Monitoring and Control: In some cases, turbine control panels support remote monitoring and control, enabling operators to access and manage the turbine system from a centralized location.

These features collectively contribute to the safe and efficient operation of turbines in various industrial settings. Turbine control panels play a crucial role in maintaining the overall performance, reliability, and safety of turbine systems. Maintaining and repairing turbine control panels is crucial for the reliable and efficient operation of turbines in various industrial applications. Turbine control panel spares and repair involve having a stock of spare parts and the capability to perform maintenance and repairs when necessary. Here are at Protonex, we consider:

Spares

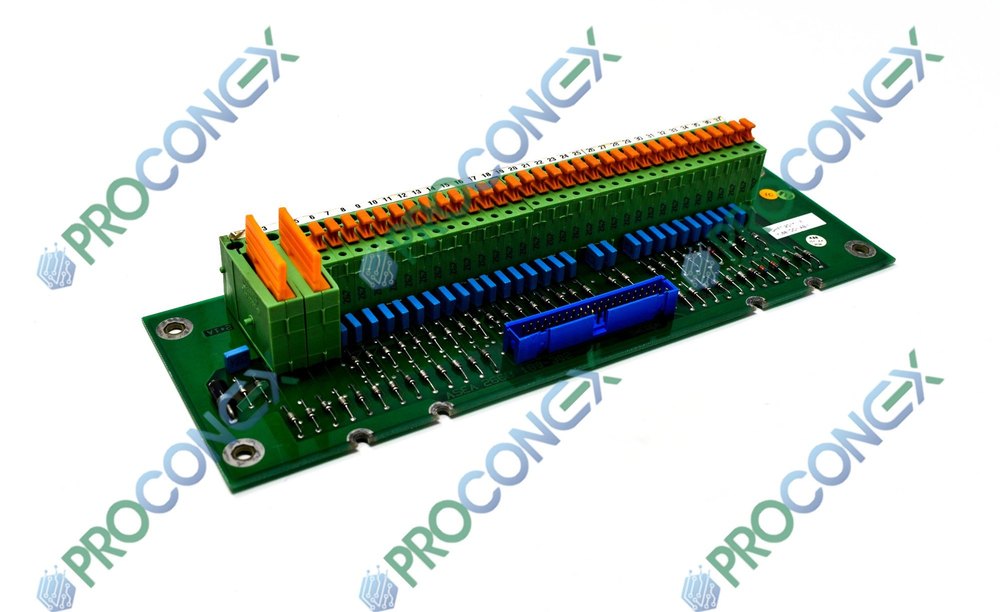

- We keep a stock of essential spare parts for the turbine control panel, including components like controllers, interface modules, circuit boards, sensors, switches, and indicators.

- We build connections with dependable suppliers for turbine control panel components, ensuring that you can promptly acquire essential spare parts when required.

- We maintain detailed documentation for the turbine control panel, including a comprehensive list of components, part numbers, and specifications, and we also assist in sourcing the correct spare parts by providing valuable information.

- In our design or upgrade of turbine control panels, we also think about adding backup options to important components, helping to reduce downtime if a part fails.

- We make certain that spare parts undergo testing and meet quality standards before being included in the inventory, ensuring the reliability and performance of the turbine control system.

Repairs

- We have diagnostic tools and equipment ready to address any issues with the turbine control panel, which may include multimeters, oscilloscopes, and specialized diagnostic software.

- Our team of control system engineers, electricians, and instrumentation specialists is trained to diagnose and fix issues with turbine control panels.

- We also establish a routine maintenance schedule for the turbine control panel, conducting inspections, cleaning, and testing of components to identify potential issues before they can cause a failure.

- We create an emergency response plan that outlines the steps to take in the event of a turbine control panel failure, including procedures for swiftly obtaining spare parts and carrying out necessary repairs.

- We maintain updated documentation and manuals for the turbine control panel, providing valuable information for efficient troubleshooting and issue resolution.

- We offer continuous training programs for maintenance personnel to keep them updated on the latest technologies and best practices for repairing turbine control panels.

- We collaborate with original equipment manufacturers (OEMs) for turbine control panels, offering support, technical assistance, and genuine spare parts.

Testing & Certification

- Visual Inspection: We will conduct a comprehensive visual inspection of the turbine control panel, examining it closely for any physical damage, loose connections, and signs of wear or deterioration.

- Functional Testing: We will execute functional tests to verify the proper operation of all components within the control panel. This involves testing the functionality of switches, indicators, relays, and other control devices to ensure they perform as intended.

- Electrical Testing: We will carry out electrical tests to confirm appropriate voltage levels, continuity, and insulation resistance. Additionally, we will inspect for any short circuits or open circuits that might impact the performance of the control panel.

- Safety System Testing: If the control panel incorporates safety systems, we will conduct tests to confirm the functionality of emergency shutdown systems, alarms, and other safety features.

- Communication Testing: We will test the communication interfaces to ensure seamless connectivity with the turbine control system and other relevant devices. Our objective is to verify compatibility with communication protocols commonly utilized in the industrial setting.

- Environmental Testing: We will subject the control panel to comprehensive environmental testing to evaluate its performance under varying conditions, including temperature fluctuations, humidity levels, and exposure to vibration.

- EMC/EMI Testing: We will conduct electromagnetic compatibility (EMC) and electromagnetic interference (EMI) testing to guarantee that the control panel does not cause interference with or experience disruptions from other electronic devices.

- Certification Compliance: We will ensure that the turbine control panel adheres to pertinent industry standards and certifications, encompassing those related to electrical safety, environmental protection, and functional safety standards.

- Documentation Review: We will review all documentation accompanying the control panel, encompassing test reports, certificates of compliance, wiring diagrams, and user manuals.

- Quality Assurance: We will implement a comprehensive quality assurance process to verify that the control panel aligns with the necessary quality standards. This includes checking for ISO certifications and adherence to quality management systems.

- Traceability: We will ensure the traceability of components within the control panel by maintaining detailed records of the source and specifications of each component. This practice is crucial for accountability and facilitates future maintenance efforts.

- Integration Testing: We will conduct integration tests with the turbine control system and other associated devices to confirm seamless integration and ensure proper communication.

Spare Parts & Repairs Availability

Services & Solutions at Proconex for Turbine Control Panel

Reliable Expertise

With years of experience, our team brings reliable expertise to every spares and repair service we provide.

Quality Assurance

We ensure that all spare parts and repairs meet the highest quality standards, contributing to the long-term reliability of your turbine control parts and spares.

Customer Support

Our dedicated support team is ready to assist you. Whether you need guidance on spare parts or emergency repairs, we are just a call away.

Contact Us Today !

Ensure the smooth operation of your turbine systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your turbine control panels.