Sugar Plants

Sugar plants, also known as sugar mills or sugar factories, are industrial facilities where sugar is extracted from sugar cane or sugar beet through a series of processes. Sugar plants, like any industrial facility, require regular maintenance, repairs, and replacement of spare parts to ensure smooth operations and maximize efficiency.

These plants are vital components of the sugar industry, which plays a significant role in the global economy. Here’s an overview of the typical processes involved in a sugar plant:

- Harvesting: Sugar cane or sugar beet is harvested from fields when it reaches maturity. The timing of the harvest is crucial to ensure maximum sugar content.

- Transportation: After harvesting, the sugar cane or sugar beet is transported to the sugar plant for processing. This is often done using trucks, rail, or sometimes even barges, depending on the location of the plantation and the plant.

- Cleaning and Preparation: Upon arrival at the plant, the sugar cane or sugar beet undergoes cleaning and preparation to remove any debris, dirt, or extraneous matter.

- Extraction: The extraction process involves extracting the sugar juice from the sugar cane or sugar beet. This is typically done through crushing or shredding the raw material and then pressing it to extract the juice.

- Clarification: The extracted juice contains impurities such as plant materials, soil, and other substances. Clarification involves the removal of these impurities through processes such as filtration and the use of clarifying agents.

- Concentration: The clarified juice is then concentrated through evaporation to increase the sugar content.

- Crystallization: The concentrated juice is seeded with sugar crystals, initiating the crystallization process. As the sugar crystals grow, they attract and incorporate more sugar molecules from the surrounding solution.

- Separation and Drying: Once the sugar crystals have reached the desired size, they are separated from the remaining liquid in a centrifuge. The separated sugar crystals are then dried to remove excess moisture.

- Packaging and Distribution: The dried sugar crystals are packaged into various sizes and formats for distribution to consumers, industrial users, and other customers.

In addition to sugar, sugar plants may also produce other by-products such as molasses, which is a thick, dark syrup left over from the sugar extraction process. Molasses can be used in various industries, including food production, animal feed, and the manufacture of alcoholic beverages.

Sugar plants are often located in regions where sugar cane or sugar beet cultivation is prevalent, such as tropical and subtropical areas for sugar cane and temperate regions for sugar beet. These plants play a vital role in providing a crucial ingredient for a wide range of food and beverage products consumed worldwide.

In sugar plants, turbine control systems spares, industrial and automation spares, and control and instrumentation spares are essential for efficient and uninterrupted production processes. Here’s a breakdown of the specific needs and the importance of spares parts procurement and repair services in these areas:

- Turbine Control Systems Spares:

- Turbine control systems are used in sugar plants for power generation from bagasse, a byproduct of sugar cane processing.

- Spare parts for turbine control systems include actuators, sensors, control panels, and safety devices.

- Timely replacement of components ensures continuous power generation, which is crucial for running various operations in the sugar plant, such as milling, boiling, and refining.

- Industrial and Automation Spares:

- Industrial automation systems are integral to sugar plants for controlling processes like material handling, conveying, and packaging.

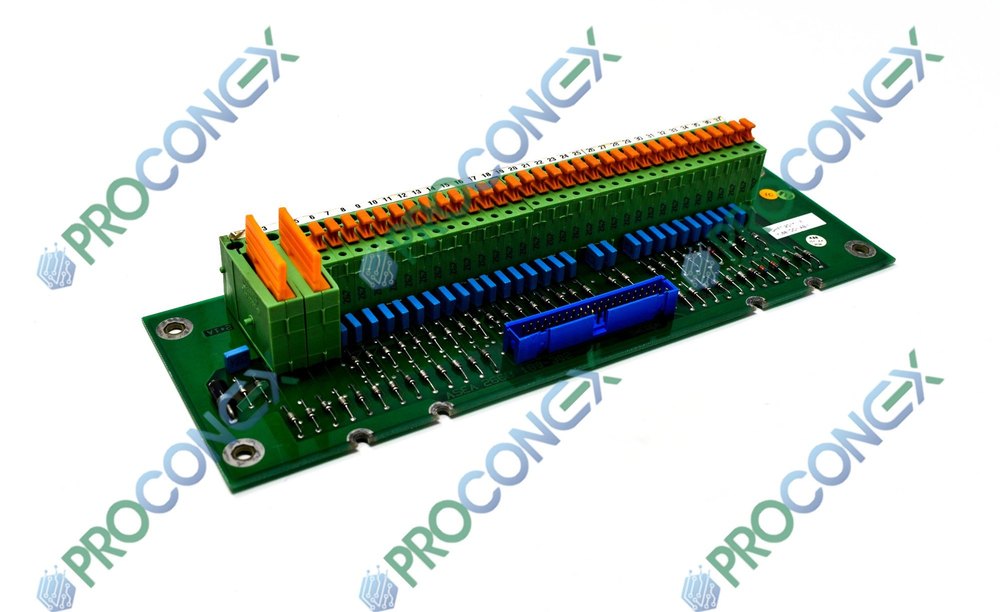

- Spare parts for industrial automation systems comprise PLCs, HMIs, motors, drives, sensors, and networking equipment.

- Access to spare parts facilitates quick responses to equipment failures, minimizing downtime and optimizing productivity in critical sugar production processes.

- Control and Instrumentation Spares:

- Control and instrumentation systems monitor and regulate parameters such as temperature, pressure, flow, and quality in sugar manufacturing.

- Spare parts for control and instrumentation systems include valves, transmitters, analyzers, control panels, and communication devices.

- Availability of spare parts enables efficient troubleshooting and repair of equipment malfunctions, ensuring the reliability and quality of sugar production.

- Spares Parts Procurement:

- Procuring spare parts for sugar plants involves sourcing components from reliable suppliers who can provide genuine parts promptly.

- Prioritizing OEM-approved parts ensures compatibility, reliability, and optimal performance within the specific operating conditions of sugar manufacturing facilities.

- Effective inventory management practices, such as predictive maintenance and strategic stocking, help minimize downtime and optimize costs associated with spare parts procurement.

- Repair Services:

- Repair services provided by experienced technicians are essential for promptly addressing equipment breakdowns and malfunctions in sugar plants.

- Emergency repair services offer rapid responses to critical failures, minimizing downtime and preventing potential production losses.

- Comprehensive repair services encompass diagnosis, repair, testing, and commissioning to ensure equipment reliability and compliance with safety standards.

In summary, efficient spares parts procurement and reliable repair services are critical for maintaining the efficiency, reliability, and quality of turbine control systems, industrial automation systems, and control and instrumentation systems in sugar plants. Collaborating with trusted suppliers and service providers is vital for ensuring uninterrupted operations and minimizing risks associated with equipment failures in sugar manufacturing.

Spare Parts & Repairs Availability

Contact Us Today !

Ensure the smooth operation of your industrial systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your control panels.