Steel Plants

Steel plants, also known as steelworks or steel mills, are industrial facilities where raw materials such as iron ore, coal, and limestone are transformed into steel. In steel plants, industrial spares and repair services are essential for ensuring uninterrupted operation, maintaining productivity, and extending the lifespan of critical equipment and machinery.

The steelmaking process typically involves several stages, including:

- Ironmaking: This process involves the extraction of iron from iron ore using a blast furnace. Iron ore, coke (a form of coal), and limestone are charged into the furnace, where the coke serves as both a fuel and a reducing agent, breaking down the iron ore into molten iron.

- Steelmaking: After the iron is produced in the blast furnace, it is then refined into steel through various methods. The most common steelmaking process is the basic oxygen furnace (BOF) method, where the molten iron is combined with scrap steel and oxygen to remove impurities such as carbon, sulfur, and phosphorus.

- Secondary Refining: In some cases, additional refining processes are employed to further improve the quality of the steel. These processes may include ladle metallurgy, vacuum degassing, or electroslag remelting.

- Casting: Once the steel has been refined to the desired composition, it is poured into molds to solidify into various shapes and forms. This can include ingots, slabs, blooms, or billets, depending on the intended use of the steel.

- Finishing: The final stage of steel production involves various finishing processes to achieve the desired surface finish and dimensions. This may include hot rolling, cold rolling, annealing, and coating.

Steel plants can vary in size and complexity, ranging from small-scale mini mills to large integrated steel complexes that encompass multiple production facilities and downstream processing operations. The location of steel plants is often determined by factors such as access to raw materials, energy sources, transportation infrastructure, and market demand.

In steel plants, the availability of turbine control systems spares, industrial and automation spares, and control and instrumentation spares is crucial for maintaining smooth operations and ensuring the efficiency of production processes. Here’s an overview of the specific needs and the importance of spares parts procurement and repair services in these areas:

- Turbine Control Systems Spares:

- Turbine control systems are utilized in steel plants for various purposes, such as power generation and operating critical machinery.

- Spare parts for turbine control systems include actuators, sensors, control panels, and safety devices.

- Timely replacement of worn-out or faulty components is essential to prevent downtime and ensure the continuous operation of turbines, which are integral to various processes in steel manufacturing.

- Industrial and Automation Spares:

- Industrial automation systems are indispensable in steel plants for controlling numerous operations, including material handling, smelting, and rolling processes.

- Spare parts for industrial automation systems comprise PLCs, HMIs, motors, drives, sensors, and networking equipment.

- Having readily available spare parts facilitates swift responses to equipment failures, minimizing disruptions and optimizing productivity in critical steel production operations.

- Control and Instrumentation Spares:

- Control and instrumentation systems are pivotal for monitoring and regulating parameters such as temperature, pressure, flow, and quality in steel manufacturing processes.

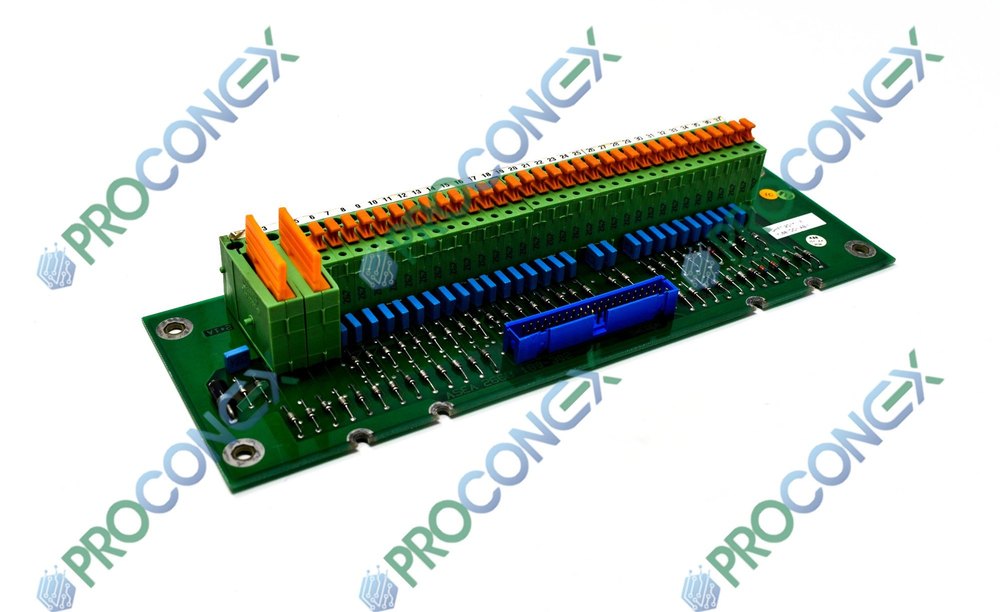

- Spare parts for control and instrumentation systems encompass valves, transmitters, analyzers, control panels, and communication devices.

- Access to spare parts enables efficient troubleshooting and repair of equipment malfunctions, ensuring the reliability and safety of steel production operations.

- Spares Parts Procurement:

- Procuring spare parts for steel plants involves establishing partnerships with reliable suppliers capable of delivering genuine components promptly.

- Prioritizing OEM-approved parts ensures compatibility, reliability, and optimal performance within the demanding operating conditions of steel manufacturing facilities.

- Effective inventory management practices, such as predictive maintenance and strategic stocking, are vital for minimizing downtime and optimizing costs associated with spare parts procurement.

- Repair Services:

- Repair services conducted by experienced technicians are essential for promptly addressing equipment breakdowns and malfunctions in steel plants.

- Emergency repair services offer rapid responses to critical failures, minimizing downtime and preventing potential production losses.

- Comprehensive repair services encompass diagnosis, repair, testing, and commissioning to uphold equipment reliability and compliance with safety standards.

In conclusion, efficient spares parts procurement and reliable repair services are indispensable for maintaining the efficiency, reliability, and safety of turbine control systems, industrial automation systems, and control and instrumentation systems in steel plants. Collaborating with trusted suppliers and service providers is crucial for ensuring uninterrupted operations and minimizing risks associated with equipment failures in the demanding environment of steel manufacturing.

Spare Parts & Repairs Availability

Contact Us Today !

Ensure the smooth operation of your industrial systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your control panels.