Refineries

In the refining industry, the availability of industrial and automation control and instrumentation spares, along with efficient repair services, is crucial for maintaining the reliability, safety, and efficiency of refining processes. Here are key considerations related to control and instrumentation spares and repairs in the context of refineries

The refining industry, often referred to as the oil refining industry or petroleum refining industry, plays a vital role in the global energy sector. Refineries are facilities where crude oil is processed to produce various refined petroleum products such as gasoline, diesel, jet fuel, heating oil, and various petrochemical feedstocks. It operates amidst complex market dynamics, stringent regulations, and continuous technological advancements. Refineries vary in size, configuration, and geographic location, adapting to global supply and demand shifts. Safety and environmental compliance are paramount, driving investment in pollution control and safety measures. Overall, refineries play a crucial role in meeting global energy needs while striving for efficiency, sustainability, and safety. Here are some key aspects of the refinery industry:

- Crude Oil Processing: The primary function of a refinery is to convert crude oil into valuable products through a series of physical and chemical processes. These processes include distillation, cracking, reforming, hydrotreating, and blending.

- Product Distribution: Refined petroleum products produced by refineries are distributed through extensive networks of pipelines, tankers, and trucks to end-users such as motorists, airlines, industrial facilities, and households.

- Market Dynamics: The refining industry is influenced by various factors including crude oil prices, demand for petroleum products, government regulations, environmental policies, and technological advancements. Refineries must adapt to changing market conditions to remain competitive.

- Environmental and Regulatory Compliance: Refineries are subject to stringent environmental regulations aimed at minimizing air and water pollution, reducing greenhouse gas emissions, and ensuring workplace safety. Compliance with these regulations requires significant investment in pollution control technologies and operational improvements.

- Refinery Configurations: Refineries can vary in size, complexity, and configuration based on factors such as the type of crude oil processed, product mix, and geographic location. Some refineries are integrated with petrochemical plants to produce a wider range of products.

- Technology Advancements: Continuous innovation in refining technologies has led to improvements in efficiency, energy conservation, and the production of cleaner fuels. Advanced refining processes such as catalytic cracking, hydroprocessing, and alkylation have enabled refineries to maximize product yields and meet quality specifications.

- Global Supply and Demand: The refining industry is part of a global supply chain, with refineries located around the world to meet regional demand for petroleum products. Shifts in global supply and demand dynamics, geopolitical factors, and trade policies can impact refinery operations and profitability.

- Safety and Maintenance: Safety is a top priority in refinery operations due to the hazardous nature of petroleum refining processes. Refineries implement strict safety protocols, training programs, and maintenance practices to prevent accidents and protect workers, communities, and the environment.

Overall, the refinery industry plays a critical role in meeting the world's energy needs by refining crude oil into essential products for transportation, heating, and industrial processes. As the energy landscape evolves, refineries continue to adapt and innovate to meet changing market demands and regulatory requirements.

In the refineries industry, the need for turbine control systems spares, industrial and automation spares, and control and instrumentation spares is paramount for ensuring safe and efficient operations. Here’s a detailed overview of these needs and the significance of spares parts procurement and repair services:

- Turbine Control Systems Spares:

- Turbine control systems are critical for power generation, compressors, and various mechanical operations in refineries.

- Spare parts for turbine control systems encompass actuators, sensors, control panels, and safety devices.

- Timely replacement of these components is crucial to prevent downtime and ensure the reliability of essential refinery operations.

- Industrial and Automation Spares:

- Industrial automation systems control numerous processes in refineries, including distillation, cracking, hydrotreating, and blending.

- Spare parts for industrial automation systems include PLCs, HMIs, motors, drives, sensors, and networking equipment.

- Access to spare parts minimizes disruptions, optimizing productivity and ensuring consistent product quality in refinery operations.

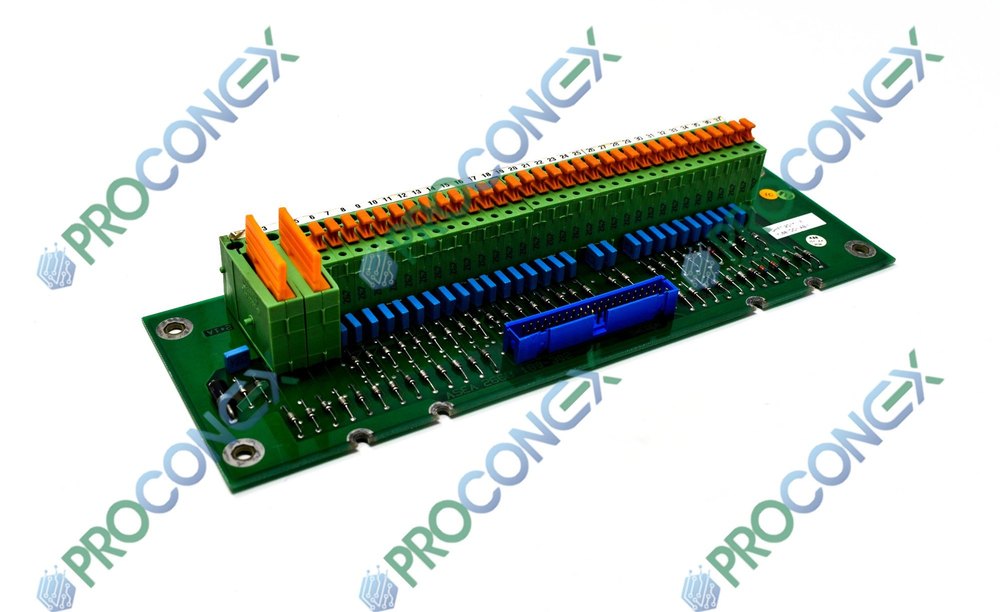

- Control and Instrumentation Spares:

- Control and instrumentation systems monitor and regulate critical parameters like temperature, pressure, flow, and composition throughout refinery processes.

- Spare parts for control and instrumentation systems comprise valves, transmitters, analyzers, control panels, and communication devices.

- Availability of spare parts enables efficient troubleshooting and maintenance, ensuring process accuracy and safety in refineries.

- Spares Parts Procurement:

- Procuring spare parts necessitates sourcing components from reliable suppliers capable of delivering genuine parts promptly.

- Prioritizing OEM-approved parts ensures compatibility, reliability, and optimal performance within the challenging operating conditions of refineries.

- Effective inventory management practices minimize downtime and optimize costs associated with spare parts procurement.

- Repair Services:

- Repair services provided by experienced technicians are vital for addressing equipment breakdowns and malfunctions promptly in refineries.

- Emergency repair services offer rapid responses to critical failures, minimizing downtime and preventing production losses.

- Comprehensive repair services encompass diagnosis, repair, testing, and validation to ensure equipment reliability and compliance with safety standards in refineries.

In summary, efficient spares parts procurement and reliable repair services are essential for maintaining the efficiency, reliability, and safety of refineries. Collaboration with trusted suppliers and service providers is crucial for ensuring uninterrupted operations, minimizing risks associated with equipment failures, and supporting overall business success in the refineries industry.

Spare Parts & Repairs Availability

Contact Us Today !

Ensure the smooth operation of your industrial systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your control panels.