All kind of Processing & Automation Plants

Processing and automation plants encompass a wide range of industries and applications, each tailored to specific needs and processes. Industrial spares and repair services are essential for maintaining the smooth operation of processing and automation plants.

Here are some examples across various sectors:

- Manufacturing Plants: These plants automate various stages of manufacturing processes, including assembly lines, packaging, quality control, and material handling. They often utilize robotic arms, conveyor belts, and computer-controlled machinery to streamline production.

- Food Processing Plants: Food processing plants automate the production of food and beverages, including sorting, washing, cutting, cooking, and packaging. Automation in these plants improves efficiency, consistency, and hygiene standards.

- Chemical Processing Plants: Chemical processing plants automate the production of chemicals, petrochemicals, pharmaceuticals, and other related products. They involve complex processes such as mixing, reaction, distillation, and purification, which are often controlled by sophisticated computer systems.

- Water Treatment Plants: These plants automate the treatment of water for various purposes, including drinking water supply, wastewater treatment, and industrial water reuse. Automation technologies help monitor water quality, regulate chemical dosing, and manage filtration processes.

- Power Plants: Power generation plants, including coal, gas, nuclear, hydroelectric, and renewable energy plants, utilize automation to control and optimize energy production processes. This includes monitoring equipment performance, regulating power output, and ensuring safety protocols.

- Mining and Mineral Processing Plants: Automation in mining and mineral processing plants enhances efficiency and safety by controlling excavation, transportation, crushing, grinding, and separation processes. Automated systems also monitor equipment condition and manage resources effectively.

- Automotive Assembly Plants: Automotive assembly plants automate the production of vehicles, including welding, painting, and final assembly processes. Robots play a significant role in performing repetitive tasks with precision and speed.

- Textile Processing Plants: Textile processing plants automate various stages of textile manufacturing, such as spinning, weaving, dyeing, printing, and finishing. Automation improves productivity, reduces labor costs, and ensures consistent product quality.

- Bioprocessing and Biomanufacturing Plants: Bioprocessing plants automate the production of biopharmaceuticals, vaccines, enzymes, and other biological products. They involve fermentation, cell culture, purification, and sterile filling processes controlled by advanced bioreactor and automation systems.

- Data Centers: Data centers automate the management of computing resources, including servers, storage, networking, and virtualization. Automation tools enable tasks such as provisioning, monitoring, scaling, and disaster recovery to be performed efficiently and reliably.

These examples illustrate the diverse applications of processing and automation plants across industries, highlighting their role in enhancing efficiency, quality, and safety in various manufacturing and production processes.

By providing a comprehensive range of industrial spares and repair services, suppliers and service providers play a crucial role in supporting the efficient and reliable operation of processing and automation plants across various industries. In all types of processing and automation plants, including industries like pharmaceuticals, chemical processing, food and beverage, automotive, and more, the need for turbine control systems spares, industrial and automation spares, and control and instrumentation spares is universal. Here's a comprehensive overview of these needs and the importance of spares parts procurement and repair services:

- Turbine Control Systems Spares:

- Turbine control systems are crucial for power generation, HVAC systems, and various mechanical operations in processing plants.

- Spare parts for turbine control systems include actuators, sensors, control panels, and safety devices.

- Timely replacement of these components prevents downtime and ensures the reliability of essential plant operations.

- Industrial and Automation Spares:

- Industrial automation systems control processes such as mixing, heating, cooling, filling, packaging, and more.

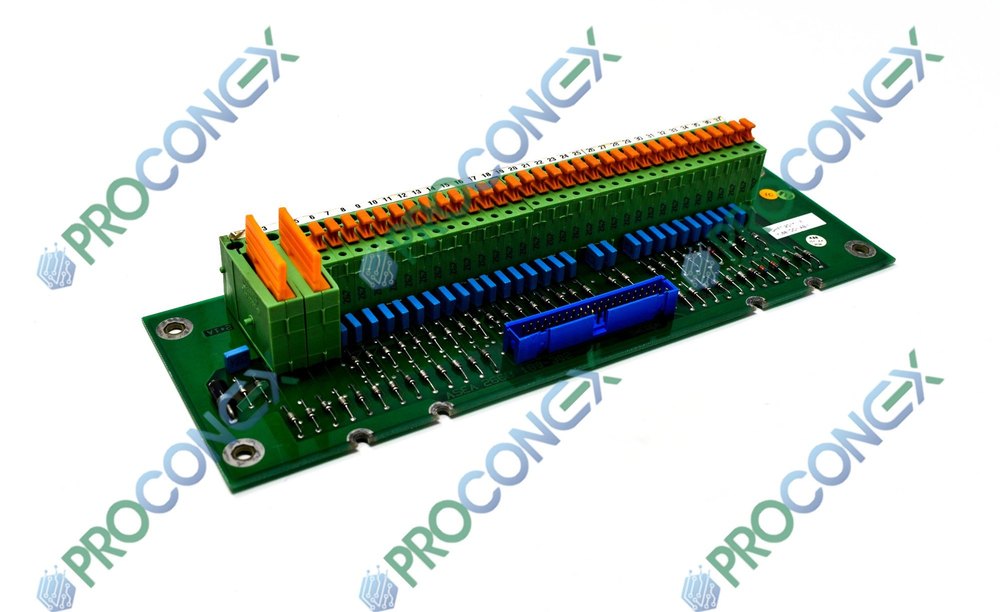

- Spare parts for industrial automation systems encompass PLCs, HMIs, motors, drives, sensors, and networking equipment.

- Access to spare parts minimizes disruptions, optimizing productivity and ensuring consistent product quality.

- Control and Instrumentation Spares:

- Control and instrumentation systems monitor and regulate critical parameters like temperature, pressure, flow, and pH levels.

- Spare parts for control and instrumentation systems include valves, transmitters, analyzers, control panels, and communication devices.

- Availability of spare parts enables efficient troubleshooting and maintenance, ensuring process accuracy and safety.

- Spares Parts Procurement:

- Procuring spare parts involves sourcing components from reliable suppliers who provide genuine parts promptly.

- Prioritizing OEM-approved parts ensures compatibility, reliability, and optimal performance within specific operating conditions.

- Effective inventory management practices minimize downtime and optimize costs associated with spare parts procurement.

- Repair Services:

- Repair services provided by experienced technicians are crucial for addressing equipment breakdowns and malfunctions promptly.

- Emergency repair services offer rapid responses to critical failures, minimizing downtime and preventing production losses.

- Comprehensive repair services encompass diagnosis, repair, testing, and validation to ensure equipment reliability and compliance with regulatory standards.

In summary, efficient spares parts procurement and reliable repair services are essential for maintaining the efficiency, reliability, and safety of processing and automation plants across various industries. Collaboration with trusted suppliers and service providers ensures uninterrupted operations, minimizes risks associated with equipment failures, and supports overall business success.

Spare Parts & Repairs Availability

Contact Us Today !

Ensure the smooth operation of your industrial systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your control panels.