Pharmaceutical Plants

Pharmaceutical plants, also known as pharmaceutical manufacturing facilities or pharmaceutical factories, are specialized facilities where medicines and pharmaceutical products are produced, processed, and packaged. Industrial spares and repairs are crucial components of ensuring the continuous and efficient operation of pharmaceutical plants.

These plants are crucial in the pharmaceutical industry as they are responsible for converting active pharmaceutical ingredients (APIs) into finished dosage forms such as tablets, capsules, injectables, and liquids, among others. Here are some key aspects of pharmaceutical plants:

- Regulatory Compliance: Pharmaceutical plants must adhere to strict regulations and guidelines set by regulatory authorities such as the Food and Drug Administration (FDA) in the United States, the European Medicines Agency (EMA) in Europe, and similar agencies in other countries. Compliance with Good Manufacturing Practices (GMP) is essential to ensure the quality, safety, and efficacy of pharmaceutical products.

- Facility Design: Pharmaceutical plants are designed to meet specific requirements for manufacturing, including cleanliness, temperature control, air quality, and contamination prevention. Cleanrooms, HVAC systems, and sterile processing areas are common features in these facilities.

- Equipment: Pharmaceutical plants use a variety of specialized equipment for manufacturing, including reactors, centrifuges, milling machines, mixers, granulators, and packaging machinery. These machines are designed to handle various processes such as mixing, granulation, drying, compression, coating, and filling.

- Quality Control: Quality control is a critical aspect of pharmaceutical manufacturing. Plants employ rigorous testing and analytical techniques to ensure the quality and consistency of raw materials, intermediates, and finished products. This includes testing for purity, potency, stability, and sterility.

- Supply Chain Management: Pharmaceutical plants rely on a complex supply chain to source raw materials, packaging components, and other supplies. Effective supply chain management is essential to ensure uninterrupted production and timely delivery of products to the market.

- Environmental Considerations: Pharmaceutical plants must also consider environmental factors such as waste management, energy consumption, and emissions control. Sustainable practices and environmental stewardship are increasingly important in the industry.

- Safety: Safety is paramount in pharmaceutical manufacturing plants. Workers are trained to follow strict protocols to minimize the risk of accidents and exposure to hazardous materials. Occupational health and safety standards are enforced to protect employees and ensure a safe working environment.

- Technology and Innovation: Advancements in technology, such as automation, robotics, and data analytics, are transforming pharmaceutical manufacturing. Plants are adopting state-of-the-art equipment and processes to improve efficiency, quality, and compliance.

Overall, pharmaceutical plants play a crucial role in producing medicines that improve public health and quality of life. They operate in a highly regulated environment and must adhere to strict quality standards to ensure the safety and efficacy of pharmaceutical products.

Industrial spares and repair services encompass the provision of spare parts for machinery and equipment, as well as maintenance, repair, and replacement services to address any issues that may arise during the manufacturing process. In pharmaceutical plants, turbine control systems spares, industrial and automation spares, and control and instrumentation spares are essential for maintaining efficient operations and ensuring the safety and quality of pharmaceutical production. Here's how these needs are addressed through spares parts procurement and repair services:

- Turbine Control Systems Spares:

- Turbine control systems may be utilized in pharmaceutical plants for power generation or to drive various equipment, such as compressors and pumps for HVAC systems or utilities.

- Spare parts for turbine control systems include actuators, sensors, control panels, and safety devices.

- Timely replacement of these components is critical to prevent downtime and maintain the reliability of utilities necessary for pharmaceutical manufacturing processes.

- Industrial and Automation Spares:

- Industrial automation systems play a crucial role in pharmaceutical plants for controlling various processes, including mixing, filling, packaging, and labeling.

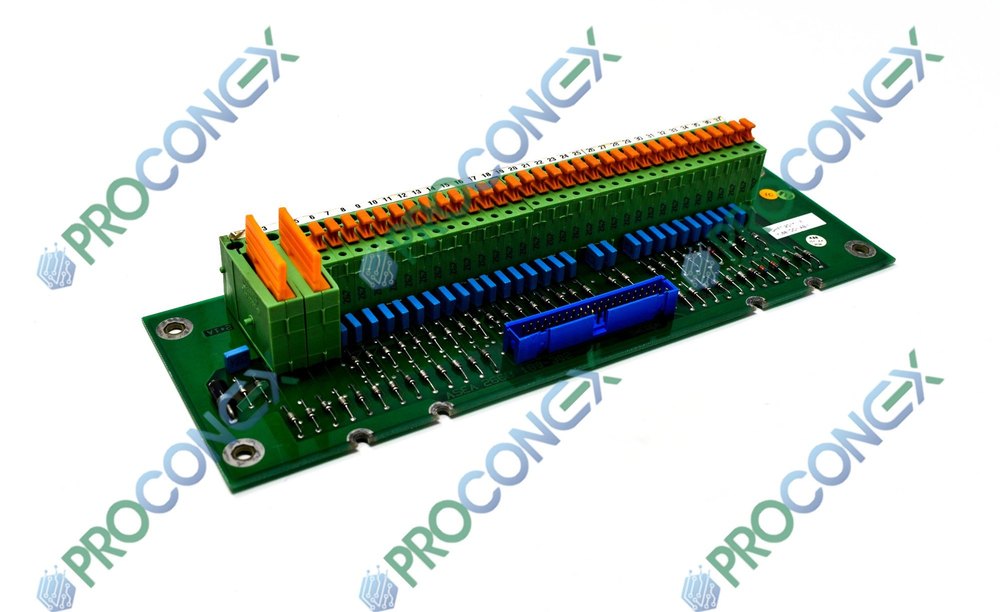

- Spare parts for industrial automation systems encompass PLCs, HMIs, motors, drives, sensors, and networking equipment.

- Access to spare parts ensures quick response to equipment failures, minimizing disruptions and ensuring consistent production of pharmaceutical products.

- Control and Instrumentation Spares:

- Control and instrumentation systems monitor and regulate critical parameters such as temperature, pressure, flow, and pH levels in pharmaceutical manufacturing processes.

- Spare parts for control and instrumentation systems include valves, transmitters, analyzers, control panels, and communication devices.

- Availability of spare parts facilitates efficient troubleshooting and repair of equipment malfunctions, ensuring the accuracy and reliability of pharmaceutical production.

- Spares Parts Procurement:

- Procuring spare parts for pharmaceutical plants involves sourcing components from reliable suppliers capable of providing genuine parts promptly.

- Prioritizing OEM-approved parts ensures compatibility, reliability, and optimal performance within the specific operating conditions of pharmaceutical manufacturing facilities.

- Effective inventory management practices, such as predictive maintenance and strategic stocking, help minimize downtime and optimize costs associated with spare parts procurement.

- Repair Services:

- Repair services provided by experienced technicians are essential for promptly addressing equipment breakdowns and malfunctions in pharmaceutical plants.

- Emergency repair services offer rapid responses to critical failures, minimizing downtime and preventing potential production losses.

- Comprehensive repair services encompass diagnosis, repair, testing, and validation to ensure equipment reliability and compliance with regulatory standards.

In conclusion, efficient spares parts procurement and reliable repair services are critical for maintaining the efficiency, reliability, and compliance of turbine control systems, industrial automation systems, and control and instrumentation systems in pharmaceutical plants. Collaboration with trusted suppliers and service providers is vital for ensuring uninterrupted operations and minimizing risks associated with equipment failures in pharmaceutical manufacturing.

Spare Parts & Repairs Availability

Contact Us Today !

Ensure the smooth operation of your industrial systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your control panels.