Paper Mills

Paper mill plants, also known simply as paper mills or paper manufacturing facilities, are industrial complexes where the process of turning raw materials into paper products takes place. Industrial spares and repairs for paper mills are crucial aspects of maintaining the efficiency and productivity of these facilities.

These plants typically consist of several key components and production stages:

- Raw Material Preparation: Paper mill plants receive raw materials such as wood logs, wood chips, recycled paper, or other fibrous materials. These raw materials are prepared for processing, which may involve debarking, chipping, shredding, or pulping.

- Pulping: The pulping process involves breaking down the raw materials into a pulp, which consists of fibers suspended in water. Pulping can be done mechanically (mechanical pulping) or chemically (chemical pulping). Mechanical pulping typically retains more of the original fiber length but results in lower-quality paper, while chemical pulping produces higher-quality paper by removing lignin and other impurities.

- Bleaching: In order to achieve the desired brightness and color of the paper, the pulp may undergo a bleaching process. This involves treating the pulp with chemicals such as chlorine dioxide, hydrogen peroxide, or sodium hydroxide to remove lignin and other colored impurities.

- Refining: The pulp may undergo refining to improve its strength, smoothness, and other properties. Refining involves passing the pulp through refining equipment such as refiners or beaters to break down the fibers further and improve their bonding ability.

- Paper Formation: The refined pulp is then formed into sheets or rolls of paper. This is typically done on a paper machine, which consists of a wire mesh conveyor belt that carries the pulp through various stages including forming, pressing, drying, and calendaring.

- Finishing: Once the paper has been formed and dried, it may undergo additional processing and finishing steps depending on its intended use. This may include coating, calendering, cutting, folding, or packaging.

Paper mill plants produce a wide range of paper products including printing paper, packaging materials, tissue paper, specialty papers, and more. These products are used in various industries such as publishing, packaging, printing, and hygiene.

It’s important to note that paper mill plants can vary in size and complexity, from small-scale operations to large industrial complexes with multiple production lines. Additionally, advancements in technology and sustainability practices are driving changes in the way paper is manufactured, with an increasing focus on recycling, energy efficiency, and environmental responsibility.

In paper mills, turbine control systems spares, industrial and automation spares, and control and instrumentation spares are essential for ensuring the smooth operation of critical machinery and processes. Here’s how these needs are addressed through spares parts procurement and repair services:

- Turbine Control Systems Spares:

- Turbine control systems are often utilized in paper mills for power generation or to drive various processes.

- Spare parts for turbine control systems include actuators, sensors, control panels, and safety devices.

- Timely replacement of these components is crucial to prevent downtime and maintain efficient power generation or process operations.

- Industrial and Automation Spares:

- Industrial automation systems play a vital role in controlling various processes within paper mills, including pulp processing, papermaking, and packaging.

- Spare parts for industrial automation systems encompass PLCs, HMIs, motors, drives, sensors, and networking equipment.

- Access to spare parts ensures quick response to equipment failures, minimizing disruptions and optimizing productivity in paper production processes.

- Control and Instrumentation Spares:

- Control and instrumentation systems monitor and regulate parameters such as pressure, temperature, flow, and quality throughout paper manufacturing processes.

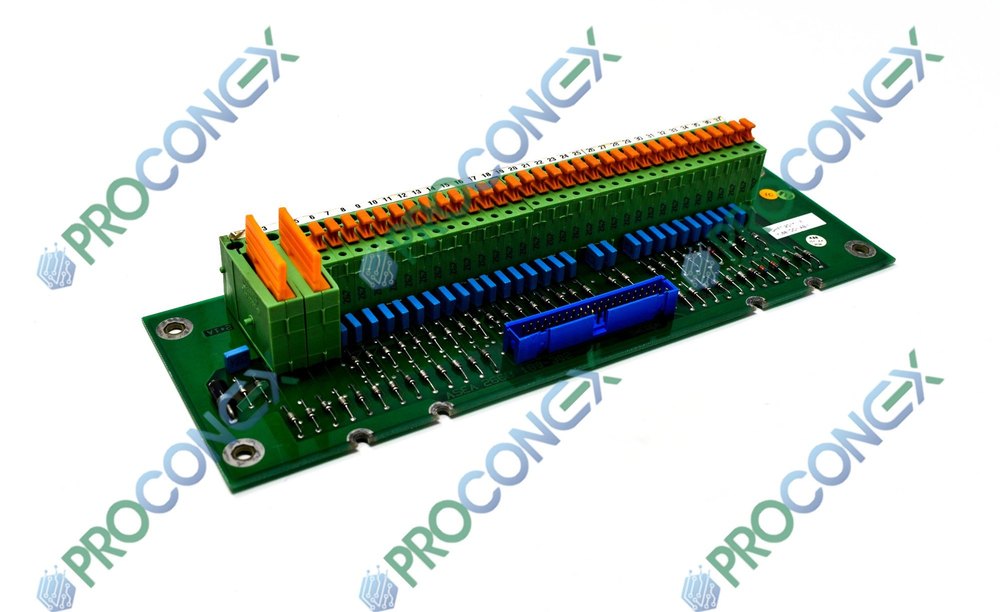

- Spare parts for control and instrumentation systems include valves, transmitters, analyzers, control panels, and communication devices.

- Availability of spare parts facilitates efficient troubleshooting and repair of equipment malfunctions, ensuring the reliability and quality of paper production.

- Spares Parts Procurement:

- Procuring spare parts for paper mills involves sourcing components from reliable suppliers capable of providing genuine parts promptly.

- Prioritizing OEM-approved parts ensures compatibility, reliability, and optimal performance within the specific operating conditions of paper manufacturing facilities.

- Effective inventory management practices, such as predictive maintenance and strategic stocking, help minimize downtime and optimize costs associated with spare parts procurement.

- Repair Services:

- Repair services provided by experienced technicians are essential for promptly addressing equipment breakdowns and malfunctions in paper mills.

- Emergency repair services offer rapid responses to critical failures, minimizing downtime and preventing potential production losses.

- Comprehensive repair services encompass diagnosis, repair, testing, and commissioning to ensure equipment reliability and compliance with safety standards.

In conclusion, efficient spares parts procurement and reliable repair services are critical for maintaining the efficiency, reliability, and quality of turbine control systems, industrial automation systems, and control and instrumentation systems in paper mills. Collaborating with trusted suppliers and service providers is vital for ensuring uninterrupted operations and minimizing risks.

Spare Parts & Repairs Availability

Contact Us Today !

Ensure the smooth operation of your industrial systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your control panels.