Other spare & repairs

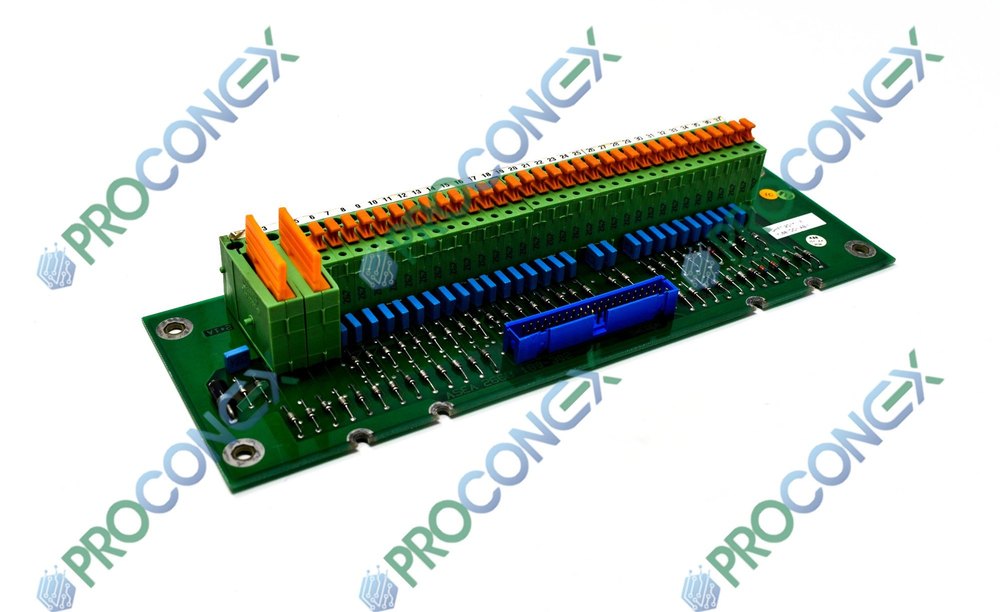

Offering comprehensive component-level testing and repairs for turbine control spares, including the specialized repair of obsolete panels that are no longer supported by the original equipment manufacturers (OEMs).

Turbine Control Component Level Testing & Repair Services

Component-level testing and repair services for turbine control spares involve assessing and fixing individual electronic or mechanical components that are part of the turbine control system. These services are crucial for maintaining the functionality and reliability of turbine control systems, especially when dealing with older or obsolete components. Here's an overview of the process:

- Diagnostic Testing:

- Identify and isolate faulty components within the turbine control spares.

- Use diagnostic tools such as oscilloscopes, multimeters, and specialized testing equipment to analyze the performance of electronic components.

- Functional Testing:

- Verify the functionality of each component to ensure it meets the specified performance criteria.

- Simulate real-world conditions to assess how components respond to various inputs and scenarios.

- Repair or Replacement:

- For identified faulty components, repair or replace them based on the severity of the issue.

- Repair activities may include soldering, replacing damaged parts, or fixing electrical connections.

- Quality Control:

- Implement stringent quality control measures to ensure that repaired or replaced components meet or exceed the original equipment manufacturer (OEM) specifications.

- Conduct thorough testing after repairs to validate the effectiveness of the performed services.

- Documentation:

- Maintain detailed records of the testing and repair process, including diagnostic results, repair actions taken, and any replacements made.

- Document the specifications and standards adhered to during the repair process.

- Compliance and Certification:

- Ensure that the repaired components comply with industry standards and regulations.

- Obtain relevant certifications or approvals to demonstrate the quality and reliability of the repaired components.

- Obsolete Component Solutions:

- Offer solutions for obsolete components, which may include sourcing replacement parts, reverse engineering, or providing alternative components that meet the required specifications.

- Testing in Operational Environment:

- Whenever possible, conduct testing in an operational environment to validate the performance of repaired components under real-world conditions.

- Continuous Improvement:

- Implement continuous improvement processes to enhance the efficiency and effectiveness of the testing and repair services.

- Stay updated with the latest technologies and methodologies in turbine control systems.

Always prioritize safety and compliance with industry standards when sourcing and installing replacement parts for critical systems like turbine controls. Additionally, consult with experts in turbine control systems to ensure that any replacements or modifications do not compromise the overall system integrity and safety.

Spare Parts & Repairs Availability

Turbine Control Supply & Repair of OBSOLETE Panels Which are not supported by the OEMS

We specialize in providing obsolete parts for Power Plants and Automobile Industries, offering out-of-production components, repairing out-of-supply control cards and modules, and leveraging an extensive global network of vendors. All repairs come with a 12-month warranty. Finding obsolete parts for turbine control systems can be challenging, but there are several strategies you can try:

OEM (Original Equipment Manufacturer)

We can contact the original manufacturer of the turbine control system. They may have a stock of older parts or can provide information on alternative solutions. Additionally, they might guide us to authorized dealers or distributors who specialize in obsolete parts.

Specialized Suppliers

Some companies specialize in supplying obsolete or hard-to-find parts for various systems. We can search for suppliers or distributors that focus on turbine control systems or industrial automation, as they may have a network for sourcing rare components.

Aftermarket Parts Manufacturers

There are companies that manufacture aftermarket or replacement parts for older systems. We can ensure that these aftermarket parts meet the necessary safety and performance standards before considering them as alternatives. It's essential to verify compatibility and adherence to standards to maintain the integrity of the original equipment.

Surplus Equipment Market

We can explore surplus equipment markets or industrial auctions. Sometimes, we might find companies selling excess inventory or decommissioned equipment, offering the possibility of obtaining the required parts. Online platforms or local auctions could serve as potential sources for acquiring these components.

Networking within the Industry

We can engage with industry forums, conferences, or online communities. Networking with professionals in the field may lead to valuable information on where to find obsolete parts. Experienced individuals might share their insights or connect us with reliable sources for obtaining the required components.

Reverse Engineering

If obtaining the exact obsolete part is impossible, we can consider reverse engineering. This involves creating a replica or finding an alternative that can perform the same function. We may work with experienced engineers or consult with specialists in the field to explore viable alternatives.

3D Printing or Custom Manufacturing

In some cases, 3D printing or custom manufacturing may be an option. This is particularly useful for non-complex components. We should ensure that the materials used meet the required specifications and standards for the turbine control system to guarantee the performance and safety of the custom-manufactured parts.

Upgrading or Retrofitting

We can evaluate the possibility of upgrading or retrofitting the turbine control system with more modern components. This might involve considering the replacement of the entire control system or integrating newer components while ensuring compatibility with the existing infrastructure.

Submit Your Product for Service

Always prioritize safety and compliance with industry standards when sourcing and installing replacement parts for critical systems like turbine controls. Additionally, consult with experts in turbine control systems to ensure that any replacements or modifications do not compromise the overall system integrity and safety.

Contact Us Today !

Ensure the smooth operation of your turbine systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your turbine control panels.