Gas Power Generation

Gas power generation refers to the process of generating electricity using natural gas as a fuel source. Industrial spares for gas power generation refer to the various components, parts, and equipment necessary for the operation, maintenance, and repair of gas power generation systems.

Gas power generation process typically involves burning natural gas in a turbine or engine to produce mechanical energy, which is then converted into electrical energy through a generator. It is a widely used method for electricity generation due to the relatively low cost and abundance of natural gas, as well as its cleaner burning compared to other fossil fuels like coal or oil. There are several types of gas power generation technologies, including:

- Gas Turbines: Gas turbines are combustion engines that burn natural gas to produce high-pressure gas, which drives a turbine to generate electricity. They are commonly used in both large-scale power plants and smaller distributed generation systems.

- Combined Cycle Power Plants: Combined cycle power plants are highly efficient gas power generation facilities that combine gas turbines with steam turbines. The exhaust heat from the gas turbine is used to generate steam, which then drives a steam turbine to produce additional electricity, increasing overall efficiency.

- Reciprocating Engines: Reciprocating engines, also known as gas-fired engines, use the combustion of natural gas in cylinders to drive pistons, which in turn drive a generator to produce electricity. These engines are often used in smaller-scale distributed generation applications, such as backup power for commercial buildings or industrial facilities.

- Microturbines: Microturbines are small-scale gas turbines typically used for distributed generation in applications such as residential or small commercial buildings, as well as in remote locations where grid connection is not feasible.

Gas power generation offers several advantages, including lower greenhouse gas emissions compared to coal or oil, greater fuel efficiency in combined cycle plants, and relatively low capital costs for smaller-scale distributed generation systems. However, concerns remain about the environmental impact of natural gas extraction and the release of methane, a potent greenhouse gas, during production and transport. Additionally, the long-term sustainability of gas power generation is being challenged as the world transitions towards renewable energy sources to mitigate climate change.

In the gas power generation industry, the availability of turbine control systems spares, industrial and automation spares, and control and instrumentation spares is crucial for ensuring reliable and efficient operations. Here's how these needs are addressed through spares parts procurement and repair services:

- Turbine Control Systems Spares:

- Turbine control systems are essential for regulating the operation of gas turbines used in power generation.

- Spare parts for turbine control systems include actuators, sensors, control panels, and safety devices.

- Timely replacement of these components is critical to prevent downtime and maintain the reliable operation of gas turbines.

- Industrial and Automation Spares:

- Industrial automation systems control various processes within gas power plants, including fuel handling, combustion, and emissions control.

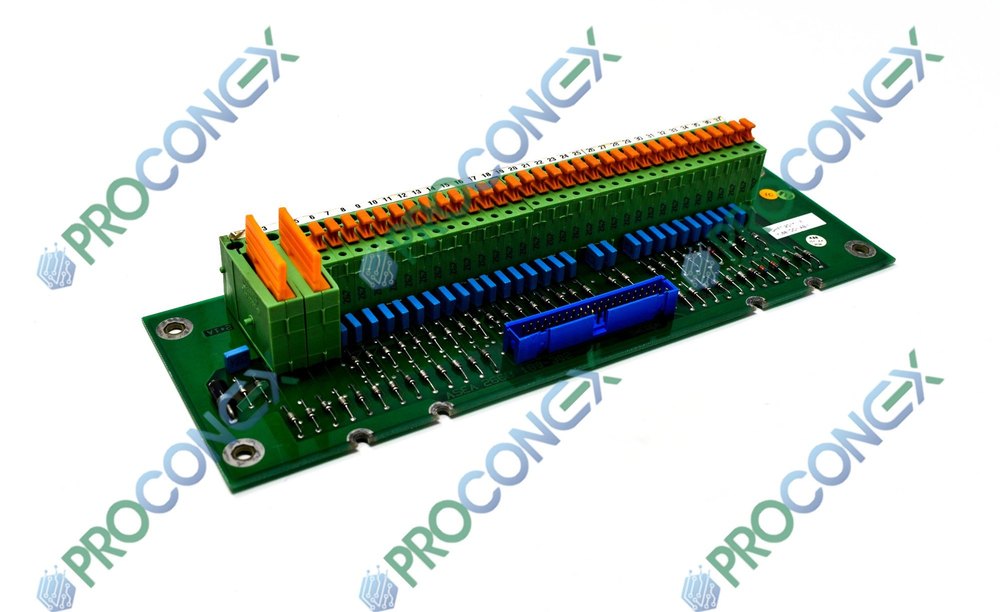

- Spare parts for industrial automation systems encompass PLCs, HMIs, motors, drives, sensors, and networking equipment.

- Access to spare parts ensures quick response to equipment failures, minimizing disruptions and optimizing efficiency in gas power generation.

- Control and Instrumentation Spares:

- Control and instrumentation systems monitor and regulate parameters such as temperature, pressure, flow, and emissions in gas power generation processes.

- Spare parts for control and instrumentation systems include valves, transmitters, analyzers, control panels, and communication devices.

- Availability of spare parts facilitates efficient troubleshooting and maintenance, ensuring accurate monitoring and control of gas power plant operations.

- Spares Parts Procurement:

- Procuring spare parts involves sourcing components from reliable suppliers capable of providing genuine parts promptly.

- Prioritizing OEM-approved parts ensures compatibility, reliability, and optimal performance within the specific operating conditions of gas power plants.

- Effective inventory management practices minimize downtime and optimize costs associated with spare parts procurement.

- Repair Services:

- Repair services provided by experienced technicians are crucial for addressing equipment breakdowns and malfunctions promptly in gas power plants.

- Emergency repair services offer rapid responses to critical failures, minimizing downtime and ensuring continuous power generation.

- Comprehensive repair services encompass diagnosis, repair, testing, and commissioning to ensure equipment reliability and compliance with safety standards in gas power generation.

In summary, efficient spares parts procurement and reliable repair services are essential for maintaining the efficiency, reliability, and safety of gas power generation plants. Collaboration with trusted suppliers and service providers is vital for ensuring uninterrupted operations, minimizing risks associated with equipment failures, and supporting overall energy production.

Spare Parts & Repairs Availability

Contact Us Today !

Ensure the smooth operation of your turbine systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your turbine control panels.