Control and Instrumentation Spares

Control and Instrumentation spares refer to the spare parts and components used in control and instrumentation systems within various industries, such as manufacturing, energy, process control, and automation.

These spares are essential for ensuring the reliable and continuous operation of control systems, measuring instruments, and other equipment that play a crucial role in monitoring and managing industrial processes.

Key components of spares include:

- Sensors and Transmitters: These devices are used to measure various parameters such as temperature, pressure, flow, and level. Examples include temperature sensors, pressure transmitters, flow meters, and level sensors.

- Control Valves and Actuators: Control valves regulate the flow of fluids in a process and are controlled by actuators. Actuators may be pneumatic, electric, or hydraulic. Spares for these components include valve positioners, actuators, and related accessories.

- Programmable Logic Controllers (PLCs): PLCs are widely used for controlling and automating industrial processes. Spares for PLCs may include replacement input/output modules, communication modules, power supplies, and programming software.

- Distributed Control Systems (DCS): DCS are complex systems that manage and control various processes in an industrial plant. Spares for DCS may include redundant controllers, communication cards, and power supplies.

- Human-Machine Interface (HMI) Devices: HMI devices provide a graphical interface for operators to interact with control systems. Spares for HMIs may include touchscreens, display units, and interface modules.

- Cables and Wiring: Essential for connecting various components in the control and instrumentation system. This includes power cables, signal cables, and communication cables.

- Power Supplies: Reliable power sources are critical for the continuous operation of control and instrumentation systems. Spares for power supplies include uninterruptible power supplies (UPS), power distribution units, and backup batteries.

- Instrumentation Enclosures and Cabinets: These protect sensitive instruments and components from environmental factors. Spares may include replacement enclosures, cabinets, and related accessories.

- Calibration Equipment: Instruments require periodic calibration to ensure accurate measurements. Spares for calibration equipment include calibration standards, test instruments, and calibration software.

- Communication Equipment: Components such as industrial networking devices and communication modules are crucial for data exchange between various components in the control system.

Having a well-maintained inventory of spares is essential for minimizing downtime, ensuring the reliability of industrial processes, and facilitating timely maintenance and repairs. Regular inspections, preventive maintenance, and strategic spare parts management are key aspects of effective control and instrumentation systems.

Control and Instrumentation Services

Control and Instrumentation services encompass a broad range of offerings designed to support the installation, maintenance, optimization, and overall performance of control systems and instrumentation in various industries. These services are crucial for ensuring that industrial processes operate efficiently, safely, and in compliance with relevant standards. Here are some key aspects of Control and Instrumentation services:

- Installation and Commissioning: Professional installation of control systems and instrumentation. Commissioning services to ensure that the systems are set up and operate as intended.

- System Integration: Integration of various control and instrumentation components to work seamlessly. Interface design and implementation to facilitate communication between different systems.

- Maintenance and Repairs: Regular scheduled maintenance services to prevent system failures and ensure reliability. Emergency repair services to address breakdowns and minimize downtime.

- Calibration Services: Periodic calibration of instruments to maintain accuracy and compliance with standards. Traceable calibration processes and documentation.

- Training Services: Training programs for operators and maintenance personnel on the proper use and maintenance of control systems. Education on system diagnostics and troubleshooting.

- Consulting and System Design: Consulting services for the design, upgrade, or optimization of control and instrumentation systems. Assistance with selecting the right components and technologies for specific applications.

- Upgrades and Retrofits: Upgrading outdated components or retrofitting systems for improved efficiency and performance. Compliance updates to meet evolving industry standards. Remote

- Monitoring and Diagnostics: Implementation of systems for remote monitoring of control systems. Real-time diagnostics to identify and address issues proactively, often leading to predictive maintenance.

- Emergency Support: 24/7 support services for emergency situations, ensuring a quick response to critical issues. Emergency hotline or on-call technicians for immediate assistance.

- Documentation and Compliance: Documentation services for system configurations, calibration records, and maintenance history. Compliance services to ensure that control systems meet industry and regulatory standards.

- Energy Management: Services focused on optimizing energy consumption within control and instrumentation systems. Implementation of energy-efficient technologies and practices.

- Cybersecurity Services: Implementation of cybersecurity measures to protect control systems from cyber threats. Regular security audits and updates to ensure system resilience against evolving risks.

- Asset Management: Asset tracking and management services to optimize the lifecycle of control and instrumentation components. Replacement planning and inventory management.

Control and Instrumentation services play a critical role in the lifecycle of industrial systems, from initial installation to ongoing maintenance and eventual upgrades. These services are essential for achieving operational excellence, minimizing downtime, and ensuring the long-term reliability of industrial processes.

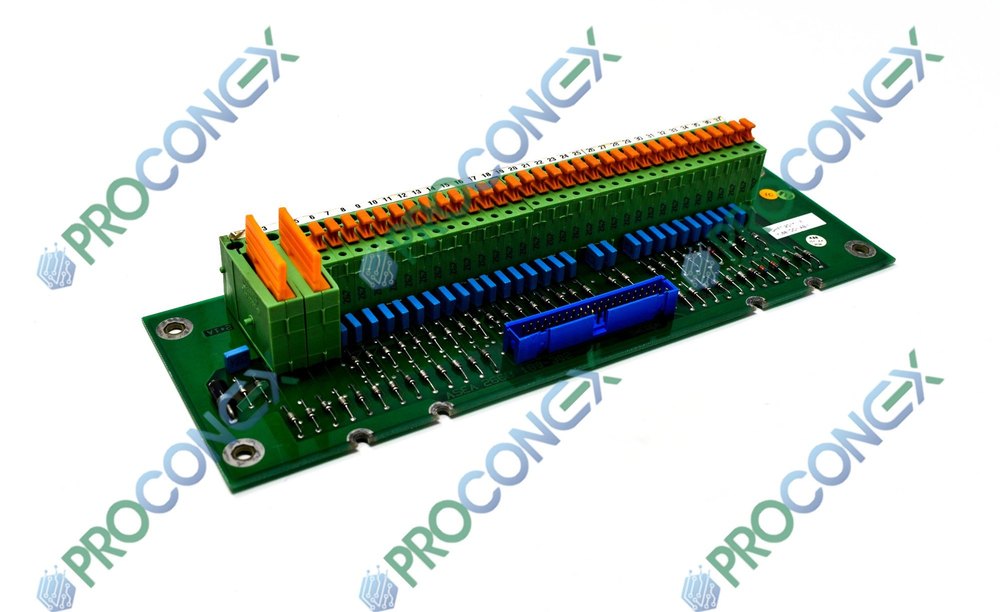

At Proconex, we take pride in offering an extensive selection of control and instrumentation spare parts, including:

Detectors

In the context of control and instrumentation, detectors play a crucial role in sensing and measuring various parameters. Depending on the specific application and industry, different types of detectors may be used. Here are some common types of detectors along with potential spare parts associated with them:

- Temperature Detectors:

- Types: Thermocouples, RTDs (Resistance Temperature Detectors), thermistors.

- Spare Parts: Replacement sensor probes, connectors, extension cables.

- Pressure Detectors:

- Types: Pressure transducers, pressure sensors.

- Spare Parts: Replacement diaphragms, seals, o-rings, electronic components.

- Level Detectors:

- Types: Float switches, ultrasonic level sensors, capacitance level sensors.

- Spare Parts: Floats, transducer elements, cables, mounting brackets.

- Flow Detectors:

- Types: Flow meters, flow switches.

- Spare Parts: Replacement sensor elements, flow tubes, electronic components.

- Gas Detectors:

- Types: Gas sensors, gas analyzers.

- Spare Parts: Sensor elements, calibration kits, filters, replacement cells.

- Position Detectors:

- Types: Encoders, potentiometers, proximity sensors.

- Spare Parts: Encoder discs, potentiometer knobs, sensor heads.

- Vibration Detectors:

- Types: Accelerometers, vibration sensors.

- Spare Parts: Mounting accessories, cables, sensor elements.

- Humidity Detectors:

- Types: Humidity sensors.

- Spare Parts: Replacement sensing elements, protective covers.

- Smoke and Fire Detectors:

- Types: Smoke detectors, heat detectors.

- Spare Parts: Replacement sensors, batteries, covers.

- Radiation Detectors:

- Types: Geiger-Muller counters, scintillation detectors.

- Spare Parts: Tubes, probes, calibration sources.

Flow

In control and instrumentation systems, flow control is critical for various processes across different industries. Here are some common spare parts associated with flow instrument

- Flow Meters:

- Types: Differential pressure flow meters, electromagnetic flow meters, ultrasonic flow meters, vortex flow meters, positive displacement flow meters.

- Spare Parts:

- Differential Pressure Flow Meters: Orifice plates, differential pressure transmitters, impulse tubing.

- Electromagnetic Flow Meters: Replacement electrodes, liners, gaskets.

- Ultrasonic Flow Meters: Transducer elements, mounting accessories.

- Vortex Flow Meters: Vortex shedding elements, sensor assemblies.

- Positive Displacement Flow Meters: Rotors, gears, bearings.

- Flow Switches:

- Spare Parts: Switch assemblies, paddles, reed switches, connectors.

- Flow Control Valves:

- Types: Control valves, throttling valves, solenoid valves.

- Spare Parts: Valve stems, diaphragms, seals, positioners, solenoid coils.

- Flow Indicators:

- Types: Visual flow indicators, flow sight glasses.

- Spare Parts: Sight glasses, gaskets, seals.

- Flow Transmitters:

- Spare Parts: Transducer elements, electronic boards, connectors.

- Flow Calibration Equipment:

- Spare Parts: Calibration standards, calibration gases, calibration seals.

- Tubing and Fittings:

- Spare Parts: Tubing, fittings, connectors, gaskets.

- Strainers and Filters:

- Spare Parts: Strainer elements, filter cartridges, gaskets.

- Flow Sensor Accessories:

- Spare Parts: Mounting brackets, protective covers, housing components.

- Signal Cables and Wiring:

- Spare Parts: Cable connectors, wiring harnesses, cable glands.

Level

In control and instrumentation systems, level measurement and control are crucial for various industrial processes. Here are common spare parts associated with level instruments:

- Level Transmitters:

- Spare Parts: Transducer elements, electronic boards, signal cables, connectors.

- Level Sensors:

- Types: Ultrasonic level sensors, capacitance level sensors, radar level sensors, float switches.

- Spare Parts: Transducer elements, sensing probes, electronic components.

- Level Gauges:

- Types: Magnetic level gauges, sight glass level gauges.

- Spare Parts: Floats, magnets, indicator boards, seals.

- Level Switches:

- Types: Float switches, capacitance level switches.

- Spare Parts: Floats, switches, electronic components.

- Valves for Level Control:

- Types: Control valves, isolation valves.

- Spare Parts: Valve stems, diaphragms, seals, positioners.

- Tubing and Fittings:

- Spare Parts: Tubing, fittings, connectors, gaskets.

- Differential Pressure Level Transmitters:

- Spare Parts: Diaphragms, impulse tubing, electronic boards.

- Guided Wave Radar Level Transmitters:

- Spare Parts: Antenna assemblies, electronics modules, signal cables.

- Solenoid Valves for Level Control:

- Spare Parts: Solenoid coils, valve diaphragms, positioners.

- Level Calibration Equipment:

- Spare Parts: Calibration standards, calibration seals, adjustment tools.

- Housings and Enclosures:

- Spare Parts: Replacement covers, gaskets, mounting brackets.

Temperature & Pressure Measuring Devices

In control and instrumentation systems, temperature and pressure measuring devices are essential for monitoring and controlling industrial processes. Here are common spare parts associated with temperature and pressure instruments:

Temperature Measuring Devices:

- Thermocouples:

- Spare Parts: Thermocouple wires, junction blocks, connectors, protection tubes.

- Resistance Temperature Detectors (RTDs):

- Spare Parts: RTD elements, extension wires, connectors, protection tubes.

- Thermowells:

- Spare Parts: Thermowell tubes, flanges, gaskets.

- Infrared (IR) Thermometers:

- Spare Parts: Replacement lenses, calibration standards, battery packs.

- Bimetallic Temperature Gauges:

- Spare Parts: Bimetallic strips, pointers, dial faces.

- Temperature Transmitters:

- Spare Parts: Transducer elements, electronic boards, signal cables, connectors.

- Temperature Controllers:

- Spare Parts: Controller modules, display units, input/output modules.

- Temperature Calibration Equipment:

- Spare Parts: Calibration standards, reference probes, calibration baths.

- Temperature Labels and Strips:

- Spare Parts: Replacement labels, adhesive strips.

Pressure Measuring Devices:

- Pressure Transmitters:

- Spare Parts: Transducer elements, electronic boards, signal cables, connectors.

- Pressure Gauges:

- Spare Parts: Bourdon tubes, pointers, dial faces, pressure relief valves.

- Pressure Switches:

- Spare Parts: Switch assemblies, diaphragms, connectors.

- Differential Pressure Transmitters:

- Spare Parts: Diaphragms, electronic boards, impulse tubing.

- Pressure Regulators:

- Spare Parts: Diaphragms, springs, adjusting screws.

- Pressure Relief Valves:

- Spare Parts: Valve discs, springs, seals.

- Manometers:

- Spare Parts: Manometer tubes, scale plates, fluid columns.

- Pressure Calibration Equipment:

- Spare Parts: Calibration standards, pressure pumps, test gauges.

- Pressure Control Valves:

- Spare Parts: Valve stems, diaphragms, seals, positioners.

- Pressure Snubbers:

- Spare Parts: Snubber elements, fittings, connectors.

Switches

Switches are essential components in control and instrumentation systems, serving various purposes such as signaling, control, and safety. Here are common types of switches and associated spare parts:

General Switch Spare Parts:

- Switch Contacts:

- Spare Parts: Replacement contact blocks, contact assemblies, contactors.

- Switch Actuators:

- Spare Parts: Replacement levers, buttons, knobs, actuators.

- Switch Enclosures:

- Spare Parts: Replacement covers, housing components, gaskets.

- Switch Mounting Hardware:

- Spare Parts: Mounting brackets, screws, nuts, washers.

- Switch Lamps and Indicators:

- Spare Parts: Indicator bulbs, LED indicators, lamp holders.

Types of Switches and Associated Spare Parts:

- Limit Switches:

- Spare Parts: Replacement cams, actuators, switches.

- Pushbutton Switches:

- Spare Parts: Pushbuttons, switch lenses, contact blocks.

- Toggle Switches:

- Spare Parts: Toggle levers, switch handles, contact blocks.

- Rotary Switches:

- Spare Parts: Replacement knobs, switch selectors, contact assemblies.

- Proximity Switches:

- Spare Parts: Sensor elements, housing components, connectors.

- Safety Switches:

- Spare Parts: Safety keys, interlock actuators, contact blocks.

- Microswitches:

- Spare Parts: Replacement plungers, levers, contacts.

- Snap Action Switches:

- Spare Parts: Replacement actuators, springs, contacts.

- Selector Switches:

- Spare Parts: Selector knobs, contact blocks, switch handles.

- Emergency Stop Switches:

- Spare Parts: E-stop buttons, mushroom actuators, contact blocks.

Specialized Switches:

- Pressure Switches:

- Spare Parts: Diaphragms, switch assemblies, connectors.

- Temperature Switches:

- Spare Parts: Bimetallic strips, sensor elements, contacts.

- Flow Switches:

- Spare Parts: Paddles, reed switches, connectors.

- Level Switches:

- Spare Parts: Floats, switches, sensor elements.

- Toggle Safety Switches:

- Spare Parts: Toggle levers, safety actuators, contact blocks.

- Proximity Safety Switches:

- Spare Parts: Sensor elements, safety keys, connectors.

Spare Parts & Repairs Availability

Our Services

Maintenance and Repair

The maintenance and repair of control and instrumentation spares involve a set of activities focused on ensuring the continued functionality and reliability of spare parts used in control systems and instrumentation within various industrial settings.

- Preventive Maintenance: ensures reliability through regular checks and proactive replacements.

- Emergency Repairs: minimize downtime with swift responses.

- Upgrades and Retrofits: Optimize efficiency and compliance for control and instrumentation spares in industrial settings.

Technical Support

Control and instrumentation spares technical support involves providing expert assistance for the installation, troubleshooting, and maintenance of control system components, ensuring optimal functionality and reliability in industrial processes.

- 24/7 Support: Round-the-clock assistance for urgent matters.

- Remote Diagnostics: Efficient troubleshooting without the need for on-site visits.

- Training Programs: Cover a range of courses aimed at educating professionals on the design, operation, maintenance, and troubleshooting of control systems and instrumentation.

Incorporating the distinctive and commendable facets of refurbishing, remanufacturing, and repairing spare parts stands as a hallmark feature that distinguishes our company from its counterparts in the industry.

Discover the benefit of our services

Minimized Downtime

Quick access to spare parts and efficient maintenance services help minimize downtime in industrial processes.

Optimized Performance

Regular calibration and maintenance ensure that control systems and instruments operate at peak performance.

Cost Savings

Proactive maintenance and timely replacements can prevent costly breakdowns and extend the lifespan of equipment.

Compliance and Safety

Ensuring that control systems meet regulatory standards and contribute to a safe working environment.

For the experts within our company, a comprehensive strategy in control and instrumentation involves ensuring the ready availability of the right spare parts and leveraging professional services. This ensures the continual reliability and efficiency of our industrial processes.

Contact Us Today !

Ensure the smooth operation of your turbine systems with our spares and repair services. Contact us today to discuss your specific needs and explore how we can contribute to the efficiency and longevity of your turbine control panels.